Introduction

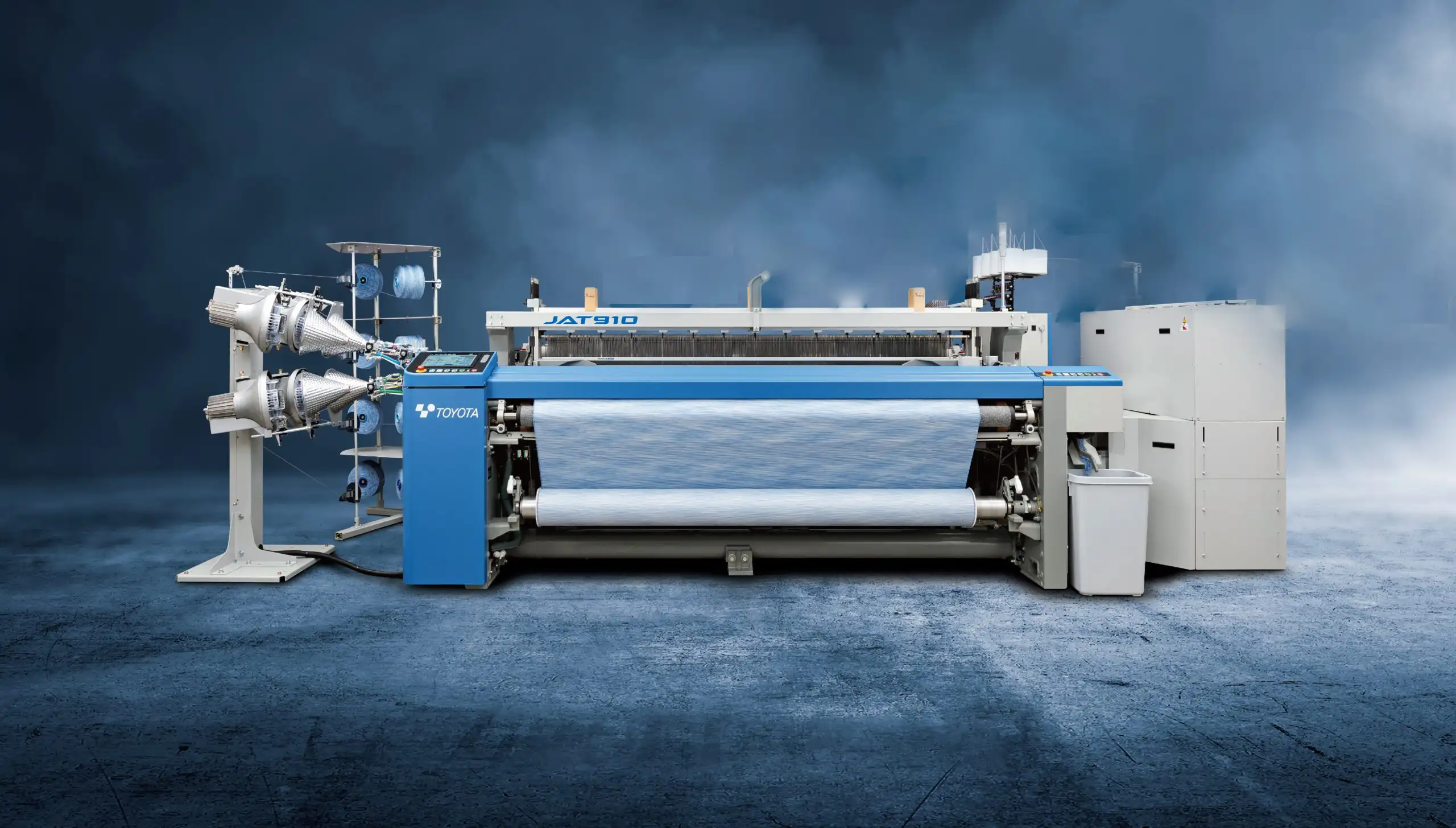

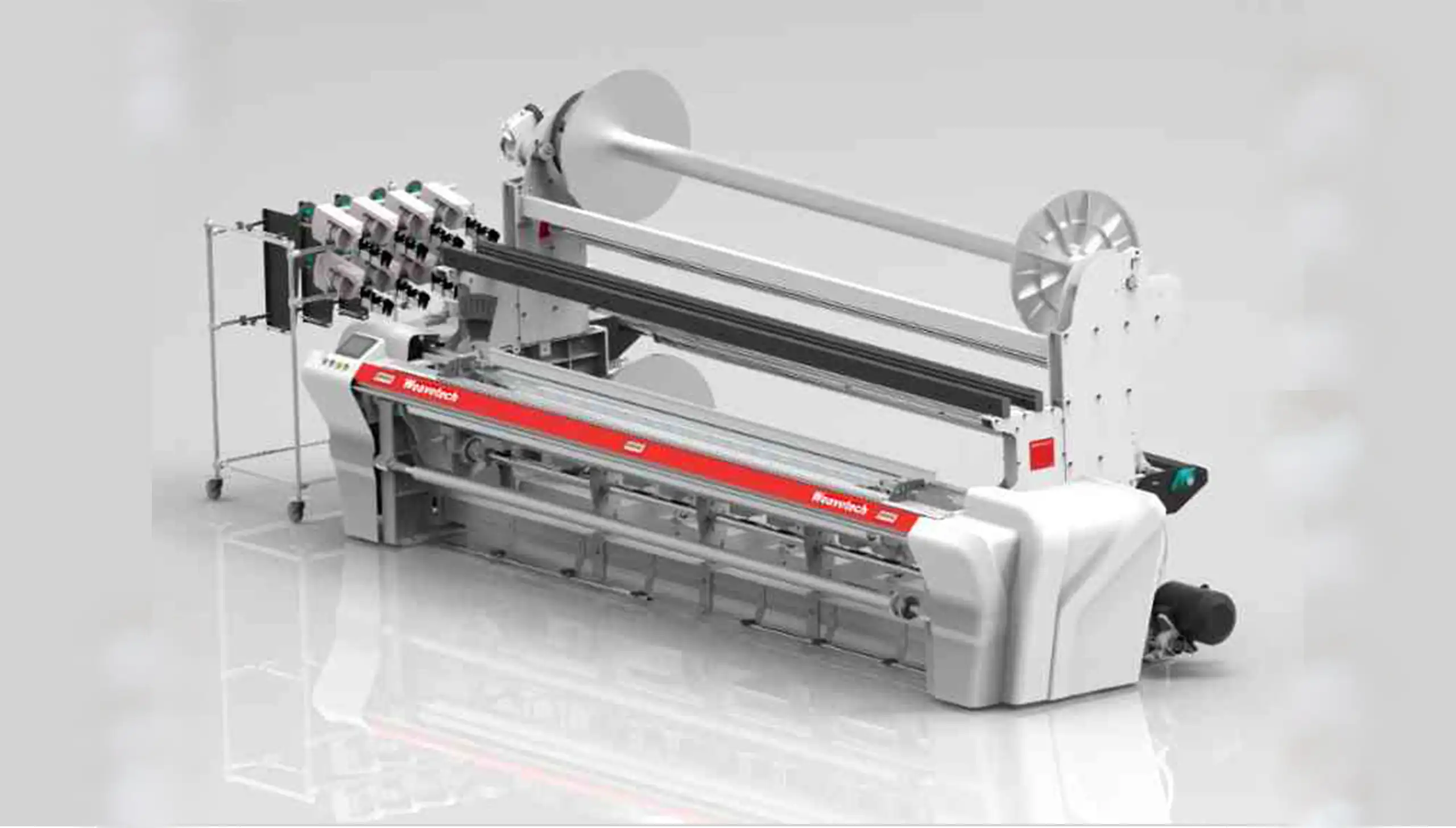

Efficient textile manufacturing relies on well-maintained machinery. Over time, spare parts in weaving, knitting, and spinning machines experience wear and tear, leading to performance issues. Replacing these parts at the right time significantly enhances productivity, minimizes downtime, and ensures consistent fabric quality.

In this blog, we’ll explore how timely spare part replacements can optimize production efficiency, reduce operational costs, and extend the lifespan of textile machines.

The Impact of Worn-Out Machine Parts on Productivity

Neglecting timely replacement of machine components can negatively affect textile manufacturing in multiple ways:

1. Frequent Downtime and Production Delays

- Worn-out parts lead to machine malfunctions, causing unexpected stoppages.

- Frequent repairs consume valuable production hours.

- Scheduled replacement prevents breakdowns, ensuring smooth operation.

2. Decline in Fabric Quality

- Defective heald frames, jacquard hooks, or tensioners result in weaving irregularities.

- Poor alignment of rollers and drive belts leads to uneven fabric tension.

- High-quality parts maintain uniformity and reduce defect rates.

3. Increased Energy Consumption

- Worn components force machines to work harder, leading to higher electricity usage.

- Properly functioning brake systems, motors, and solenoids optimize energy efficiency.

- Regular replacement of faulty parts helps cut operational costs.

4. Higher Maintenance Costs

- Delayed replacements lead to extensive wear on other interconnected parts.

- Small issues, if ignored, turn into expensive repairs or complete machine failure.

- Timely replacements reduce the need for emergency fixes and expensive overhauls.

How Timely Spare Part Replacements Enhance Productivity

Maintaining a proactive spare parts strategy helps textile manufacturers improve workflow and overall production efficiency. Here’s how:

1. Ensures Uninterrupted Production

- Machines remain in peak condition, reducing unexpected failures.

- Efficient parts like heald wires, sensors, solenoids, and dobby cams keep the production line running.

- Predictive maintenance allows for scheduled downtime, minimizing disruptions.

2. Improves Machine Longevity

- Machines last longer when essential components are replaced before failure.

- Prevents strain on drive chains, belts, and electromagnets.

- Extends the operational life of expensive textile equipment.

3. Boosts Efficiency and Output

- Precision parts like electronic controllers, harness cords, and drive systems optimize weaving speeds.

- Machines operate at their highest efficiency without interruptions.

- Higher productivity translates into increased profitability.

4. Reduces Waste and Defects

- Consistently high fabric quality reduces rework and material wastage.

- Smooth machine operation minimizes defective output.

- Enhances the reputation of manufacturers by delivering superior products.

Best Practices for Managing Spare Part Replacements

To maximize productivity, textile manufacturers should follow these best practices:

1. Maintain a Spare Parts Inventory

- Keep stock of essential replacement parts for Vamatex, Somet, Dornier, Jacquard, and Dobby machines.

- Avoid last-minute delays by planning ahead.

2. Conduct Regular Machine Inspections

- Schedule routine maintenance checks.

- Identify signs of wear in brake systems, cams, and bearings.

3. Source from Reliable Suppliers

- Use high-quality spare parts from trusted providers like Shaoxing Jainatex Trading Company Limited.

- Avoid substandard components that cause frequent failures.

4. Follow Manufacturer Guidelines

- Use genuine parts that match your machine model specifications.

- Stick to recommended replacement cycles for optimal performance.

Where to Buy High-Quality Textile Machine Spare Parts

For reliable spare parts for Somet, Vamatex, Panther, Dornier, Feeder, and Jacquard machines, choose Shaoxing Jainatex Trading Company Limited. They offer:

1. Genuine and Aftermarket Parts

- Precision-engineered components to match your machine requirements.

2. Competitive Pricing

- Affordable spare parts with bulk order discounts.

3. Fast Global Shipping

- Quick international delivery with secure packaging.

4. Expert Technical Assistance

- Support in selecting the right parts for maximum efficiency.

Conclusion

Timely replacement of textile machinery spare parts is essential for maintaining peak productivity, reducing downtime, and optimizing production efficiency. Investing in high-quality components from Shaoxing Jainatex Trading Company Limited ensures uninterrupted operations, improved fabric quality, and lower operational costs.

Stay ahead in textile manufacturing—replace worn-out parts on time and maximize your production output!