Introduction

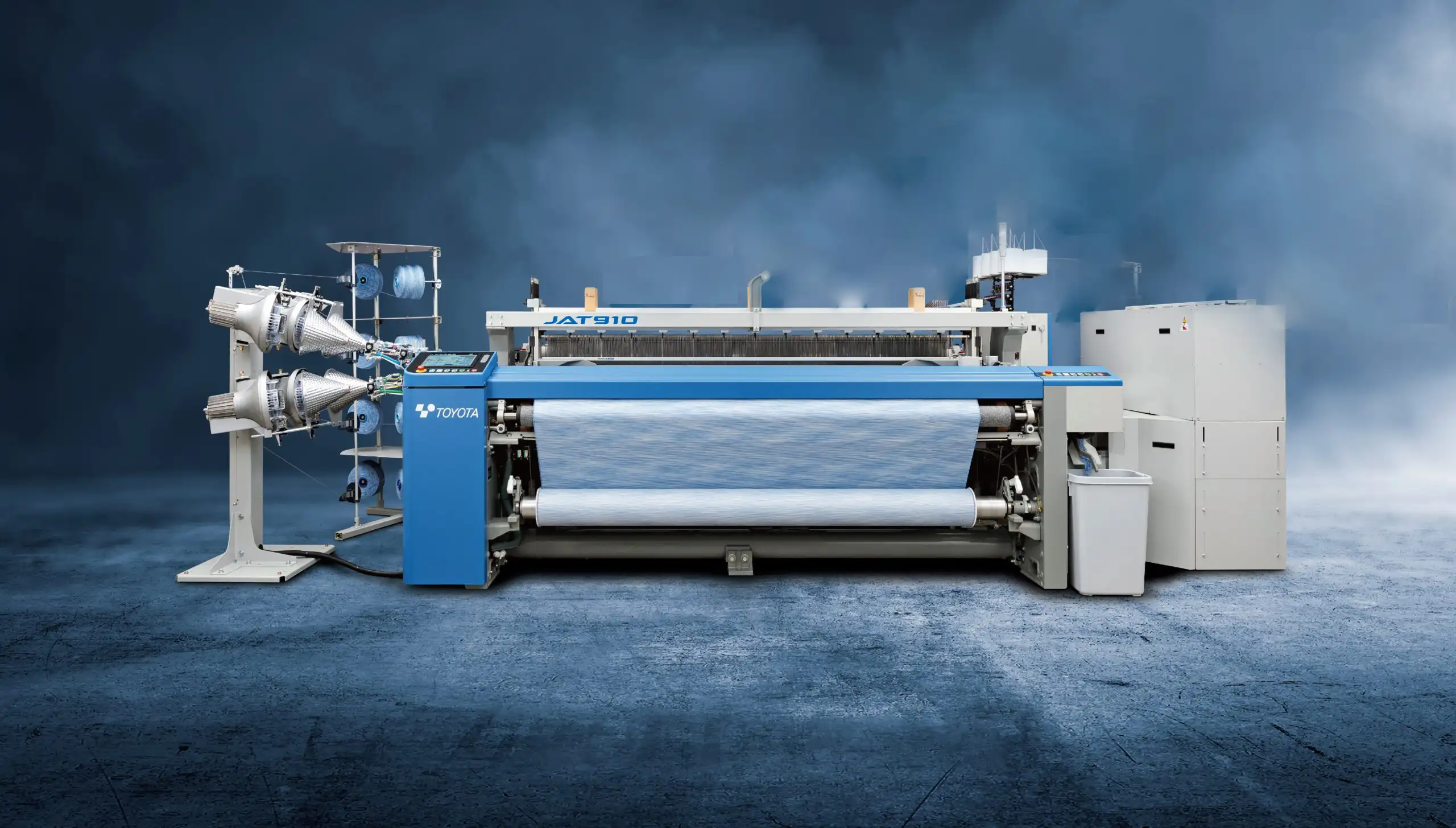

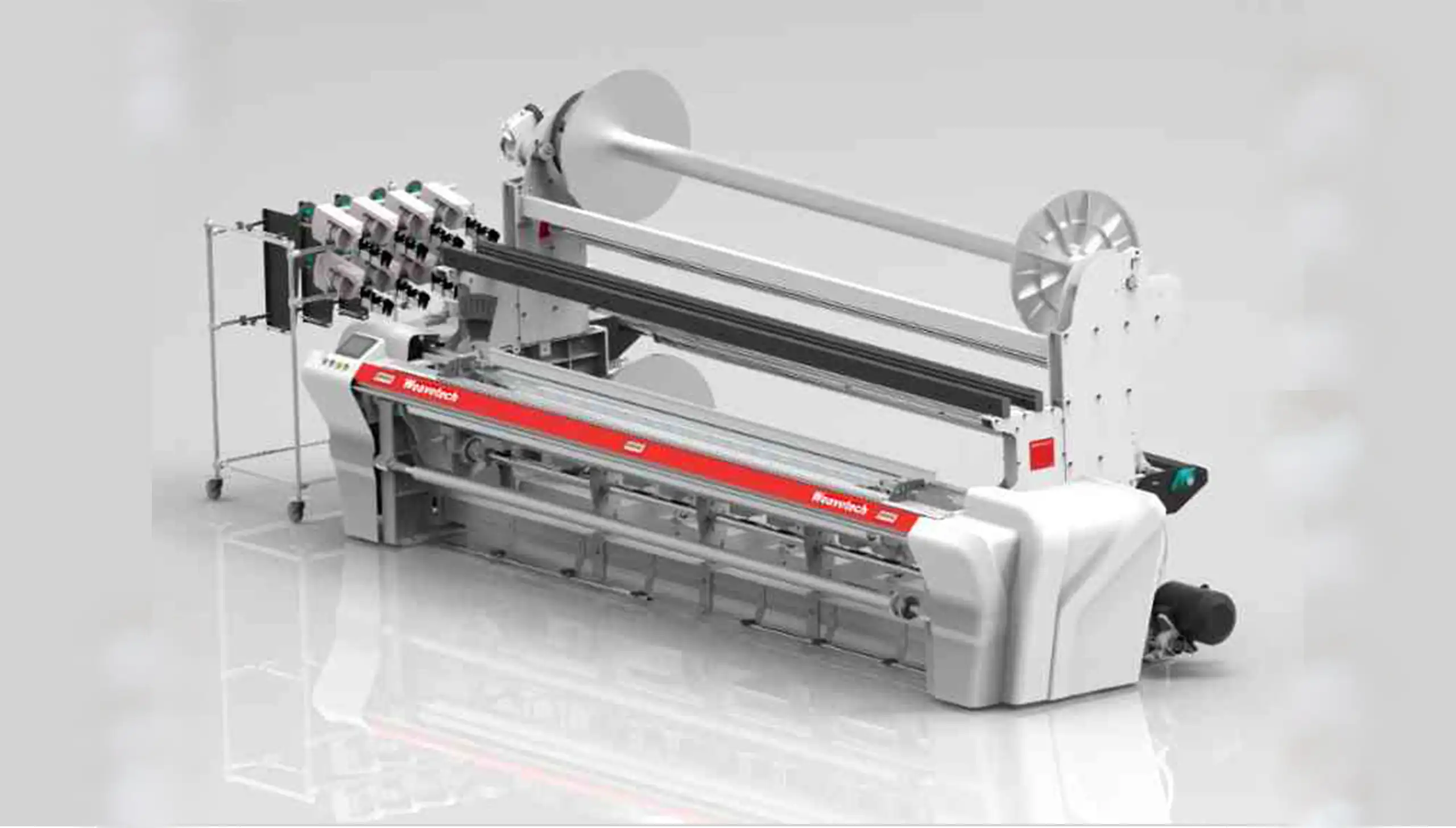

The efficiency of textile manufacturing heavily depends on the performance of textile machines. Over time, wear and tear on essential components can lead to breakdowns, production delays, and fabric defects. Choosing the right spare parts for textile machinery is crucial for ensuring smooth operations and maintaining high production standards.

In this guide, we will explore the key factors to consider when selecting spare parts, the importance of quality and compatibility, and why sourcing from Shaoxing Jainatex Trading Company Limited is the best choice for textile manufacturers.

Why Choosing the Right Spare Parts Matters

Using the wrong or low-quality spare parts can result in various operational issues, including:

- Frequent Breakdowns: Poor-quality components wear out faster, leading to unplanned downtime.

- Lower Production Efficiency: Mismatched parts can affect machine alignment and performance.

- Higher Maintenance Costs: Cheap parts may require frequent replacements, increasing long-term expenses.

- Fabric Quality Issues: Incorrectly fitted parts can lead to weaving defects, affecting product quality.

Factors to Consider When Selecting Spare Parts

To ensure you get the best performance from your textile machines, consider the following factors when purchasing spare parts:

1. Machine Compatibility

- Always check the machine model and part specifications.

- Ensure the spare part is designed for Somet, Vamatex, Dornier, Panther, Feeder, Jacquard, or Dobby machines.

- Avoid generic parts that may not fit correctly or function properly.

2. Quality and Durability

- Opt for high-quality, durable materials such as stainless steel, aluminum alloys, and reinforced polymers.

- Genuine parts last longer and reduce the risk of mechanical failure.

- Substandard parts can cause premature wear on other machine components.

3. Manufacturer Recommendations

- Refer to the machine’s manual for OEM (Original Equipment Manufacturer) specifications.

- Using recommended parts ensures proper machine operation and maintains warranty conditions.

4. Supplier Reliability

- Choose a trusted supplier like Shaoxing Jainatex Trading Company Limited.

- Ensure the supplier provides warranty coverage, technical support, and genuine parts.

- Verify the supplier’s reputation through customer reviews and industry experience.

5. Cost vs. Value

- While price is important, the cheapest option is not always the best.

- High-quality spare parts may have a higher upfront cost but save money in the long run.

- Consider bulk purchasing for better pricing and continuous supply.

Common Spare Parts for Textile Machines

Different textile machines require specialized spare parts. Here are some essential components for popular brands:

1. Somet Machine Spare Parts

- Electronic controllers

- Weft feeders

- Tensioners

- Heald frames

2. Vamatex Machine Spare Parts

- Rapier tapes

- Grippers and drive wheels

- Cutter and suction nozzles

- Jacquard module spares

3. Dornier Machine Spare Parts

- Clutch brakes

- Selvedge cutters

- Sensors and solenoids

- Guide hooks and rings

4. Panther Machine Spare Parts

- Rapier heads

- Bearings and belts

- Drive chains

- Bobbins and shuttle components

5. Jacquard & Dobby Machine Spare Parts

- Harness cords

- Hooks and knives

- Lifting modules

- Magnetic solenoids

6. Feeder Machine Spare Parts

- Rollers and tensioners

- Electronic sensors

- Drive motors

- Brake and clutch systems

Where to Buy High-Quality Textile Spare Parts

For top-quality textile machine spare parts, Shaoxing Jainatex Trading Company Limited is a trusted supplier offering:

1. Genuine and Aftermarket Spare Parts

- High-precision components designed for leading textile machinery brands.

- Reliable, long-lasting spare parts that ensure smooth operation.

2. Competitive Pricing and Bulk Discounts

- Affordable rates for premium textile spare parts.

- Special offers available for bulk purchases.

3. Fast Global Shipping

- Reliable international delivery with secure packaging.

- Ensures timely part replacement to avoid production delays.

4. Expert Technical Support

- Assistance in selecting the right spare parts for specific machines.

- Professional guidance on installation and maintenance.

Conclusion

Choosing the right textile machinery spare parts is essential for maintaining high productivity, reducing downtime, and ensuring fabric quality. By selecting compatible, high-quality parts from a trusted supplier like Shaoxing Jainatex Trading Company Limited, textile manufacturers can optimize machine performance and extend the lifespan of their equipment.

Ensure the longevity and efficiency of your textile machines—invest in the best spare parts today!