Introduction

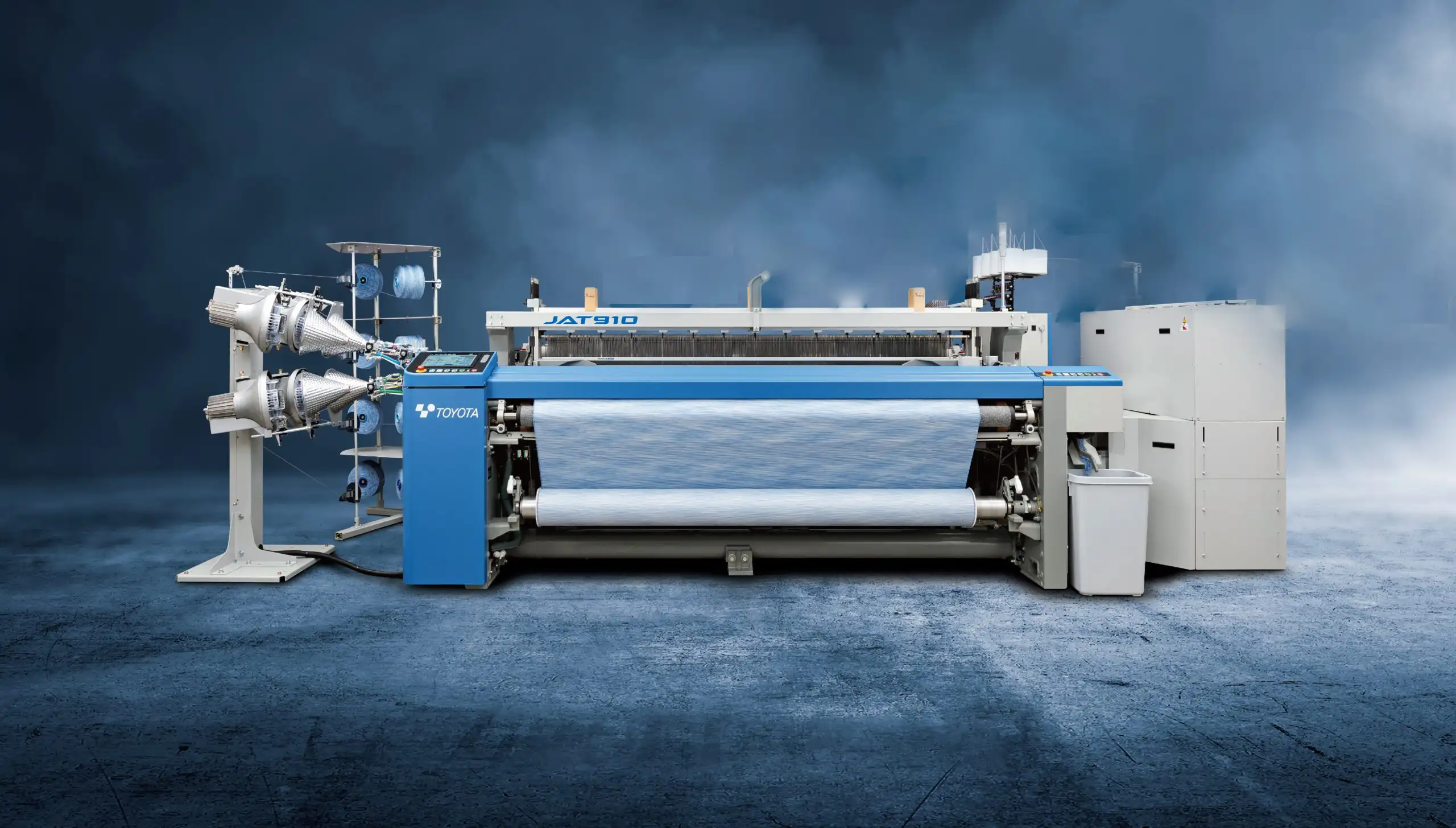

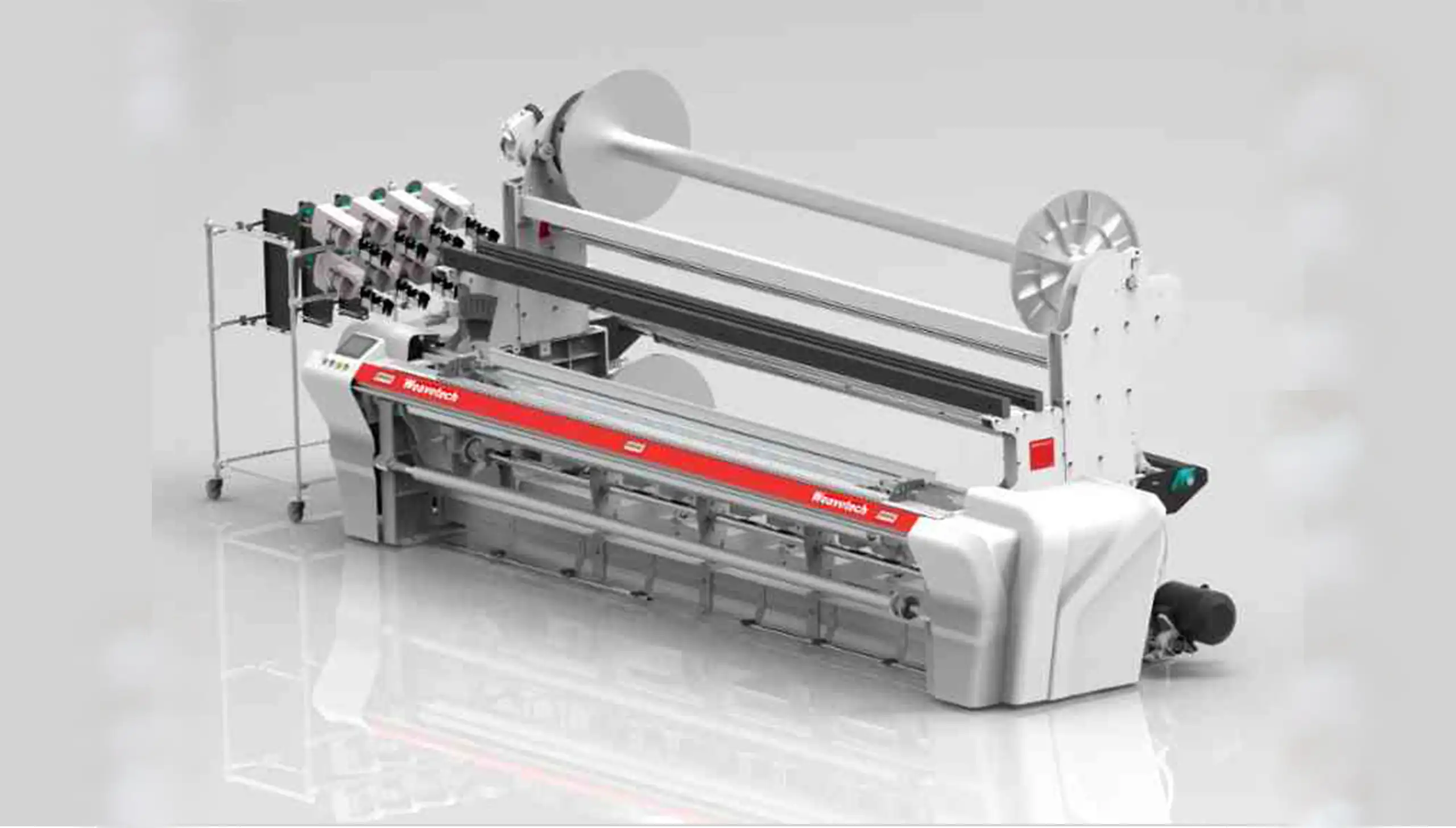

Feeder systems play a crucial role in the smooth operation of textile weaving machines. Whether you are using rapier, airjet, waterjet, or shuttleless looms, a high-quality feeder system ensures precise yarn insertion, stable tension, and improved fabric quality. However, like all mechanical components, feeders and their spare parts require regular maintenance and timely replacement to prevent disruptions in production.

This guide explores essential feeder spare parts, maintenance tips, and the best place to buy genuine feeder machine spare parts online.

Understanding Feeder Systems in Weaving Machines

Feeders are responsible for controlling the yarn tension and weft insertion in weaving looms. They help ensure a consistent yarn supply, preventing uneven weaving and fabric defects. Some of the most common types of feeders include:

- Electronic Weft Feeders (used in rapier, airjet, and waterjet looms)

- Mechanical Weft Feeders

- Roving and Bobbin Feeders

- Direct Yarn Feeders (for high-speed weaving applications)

To maintain optimal efficiency, replacing worn-out feeder spare parts is essential for minimizing downtime and ensuring high-quality textile production.

Commonly Replaced Feeder Spare Parts

Over time, various feeder components experience wear and require replacement. Below are some of the most frequently replaced feeder machine spare parts:

1. Weft Feed Rollers

- Ensures smooth and controlled weft yarn feeding.

- Available in rubber-coated and metal variants.

- Regular maintenance prevents slippage and tension loss.

2. Weft Tension Sensors

- Detects yarn tension variations and adjusts accordingly.

- Prevents excessive stress on yarn and ensures smooth weaving.

3. Weft Storage Disks and Drums

- Holds and dispenses yarn at a controlled rate.

- Essential for electronic weft feeders in high-speed looms.

4. Brake and Clutch Mechanisms

- Controls yarn release and stopping action.

- Regular replacement helps maintain accurate weft insertion.

5. Electronic Control Modules

- Used in advanced electronic feeder systems.

- Ensures synchronization between loom and feeder.

6. Feeder Drive Belts and Gears

- Transfers power to feeder components.

- Worn-out belts can cause feeder malfunctions and inconsistencies in yarn tension.

7. Yarn Guides and Tensioners

- Maintains proper alignment and prevents entanglement.

- Essential for preventing yarn breakages and defects.

How to Choose the Right Feeder Spare Parts

When selecting feeder loom spare parts, consider the following factors:

1. Compatibility: Ensure that the spare parts match your loom’s specific feeder system.

2. Genuine vs. Aftermarket Parts: Original parts ensure durability, while premium aftermarket options offer cost-effective solutions.

3. Material Quality: Look for high-performance materials such as ceramic yarn guides, durable rubber coatings, and corrosion-resistant metals.

4. Supplier Reliability: Purchase from reputable sellers like Shaoxing Jainatex Trading Company Limited.

5. Cost vs. Performance: Cheaper parts may wear out quickly, increasing maintenance costs in the long run.

Maintenance Tips for Extending Feeder Life

Proper maintenance can significantly extend the lifespan of weaving feeder spare parts. Follow these essential maintenance tips:

- Regular Cleaning: Remove dust, lint, and yarn residue to prevent clogging.

- Lubrication: Apply lubricants to moving parts such as rollers and gears to reduce friction.

- Tension Adjustments: Check and calibrate feeder tension settings regularly.

- Sensor Calibration: Ensure that electronic sensors and control modules are functioning correctly.

- Timely Replacement: Replace worn-out parts before they cause major breakdowns.

Where to Buy Genuine Feeder Spare Parts

For high-quality feeder machine spare parts, trust Shaoxing Jainatex Trading Company Limited. They provide:

1. Premium Original & Aftermarket Feeder Parts

- Compatible with various loom brands and models.

- Manufactured with high-grade materials for durability.

2. Competitive Pricing & Bulk Discounts

- Affordable spare parts for textile manufacturers.

- Special discounts on large orders.

3. Fast Global Shipping

- Reliable delivery services to textile hubs worldwide.

- Secure packaging to prevent transit damage.

4. Expert Support & Technical Assistance

- Professional guidance in selecting the right feeder parts.

- Responsive customer service for inquiries and orders.

Conclusion

Maintaining your weaving loom feeder system with high-quality feeder spare parts is crucial for seamless textile production. Whether you require weft feed rollers, tension sensors, electronic control modules, or drive belts, Shaoxing Jainatex Trading Company Limited is your trusted supplier for premium textile machinery spare parts.

Regular maintenance and timely replacement of feeder machine spare parts will help you reduce downtime, enhance fabric quality, and maximize efficiency. For the best feeder spare parts, choose Shaoxing Jainatex Trading Company Limited – your reliable partner in textile machinery spare parts.