Introduction

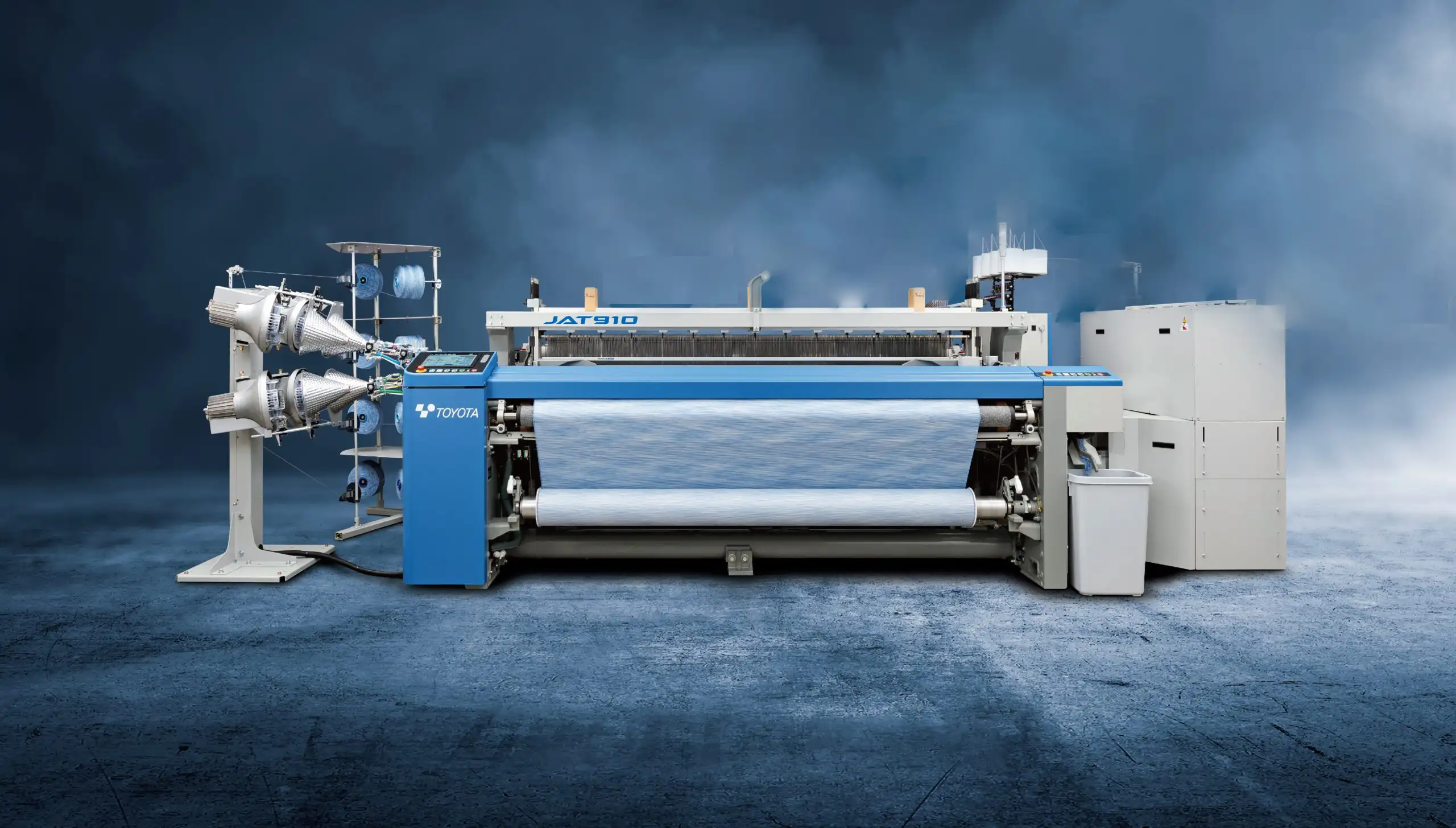

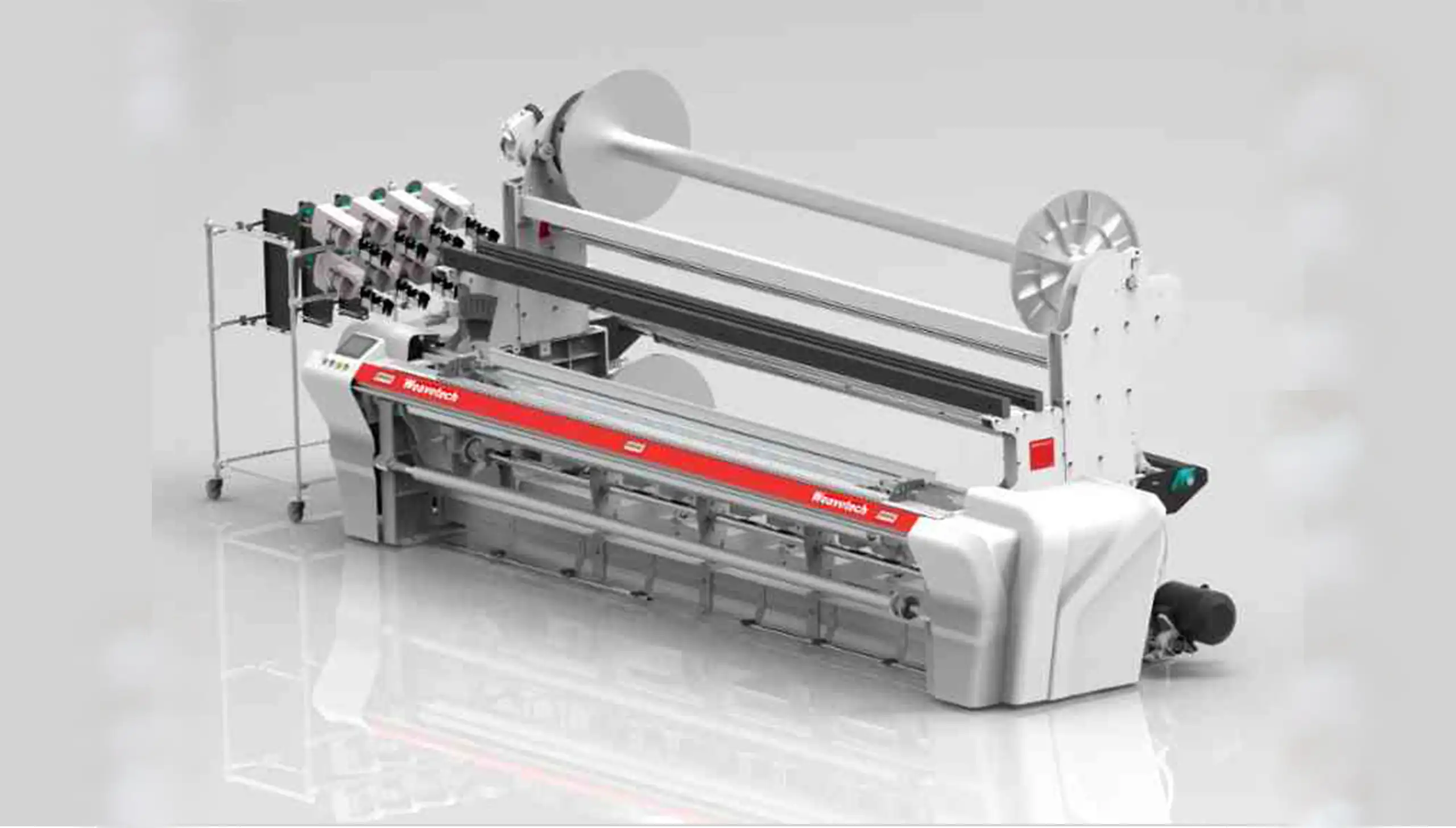

Textile machinery plays a vital role in ensuring smooth and efficient fabric production. However, over time, the components of weaving, knitting, and spinning machines wear out due to continuous usage. Replacing spare parts at the right time prevents production delays, reduces downtime, and maintains high-quality fabric output.

In this guide, we will explore the key signs indicating that your textile machine parts need replacement, the risks of delaying replacements, and the best sources for genuine textile machinery spare parts.

Signs That Textile Machine Parts Need Replacement

Knowing when to replace spare parts can save time and money while preventing major breakdowns. Below are the most common indicators:

1. Inconsistent Fabric Quality

- Uneven weaving, defects, or variations in fabric structure.

- Excessive yarn breakages or tension issues.

- Loss of pattern accuracy in Jacquard or Dobby weaving machines.

2. Increased Machine Vibrations and Noise

- Unusual rattling, grinding, or squeaking noises.

- Excessive shaking or instability during operation.

- Could indicate worn-out bearings, drive belts, or cams.

3. Frequent Production Stoppages

- Machines stopping unexpectedly or requiring frequent resets.

- Faulty electronic sensors or controllers causing errors.

- Overheating due to worn-out motors, solenoids, or cooling systems.

4. Higher Energy Consumption

- Increased power usage without any significant change in production.

- Faulty components requiring more energy to function.

- Inefficient brake and clutch systems leading to excessive power drain.

5. Excessive Wear and Tear on Moving Parts

- Visible signs of rust, corrosion, or material degradation.

- Loss of tension in harness cords, drive chains, and belts.

- Loosening or misalignment of heald frames, needles, or guides.

Risks of Delaying Spare Part Replacements

Ignoring worn-out spare parts can lead to severe consequences, including:

- Increased Downtime: Machine breakdowns can halt production, causing financial losses.

- Higher Repair Costs: Minor issues can escalate into major problems if not addressed promptly.

- Poor Fabric Quality: Defective machine parts lead to inconsistent textile output.

- Safety Hazards: Damaged parts can cause malfunctions that pose risks to workers.

Best Practices for Timely Spare Part Replacement

To maintain efficiency and avoid production disruptions, follow these best practices:

1. Conduct Regular Inspections

- Schedule preventive maintenance checks.

- Inspect key components such as tensioners, sensors, solenoids, and rollers.

- Identify early signs of wear and replace parts proactively.

2. Keep Spare Parts Inventory

- Stock essential spare parts for quick replacements.

- Track usage and reorder frequently used components in advance.

3. Follow Manufacturer Recommendations

- Refer to machine manuals for specific replacement intervals.

- Use only genuine or high-quality aftermarket parts to ensure durability.

4. Partner with a Reliable Supplier

- Choose a trusted supplier like Shaoxing Jainatex Trading Company Limited for genuine textile machine spare parts.

- Ensure the supplier offers high-quality components, competitive pricing, and fast shipping.

Where to Buy High-Quality Textile Machine Spare Parts

For reliable weaving, knitting, and spinning machine spare parts, trust Shaoxing Jainatex Trading Company Limited. They offer:

1. Premium Spare Parts for All Textile Machines

- Suitable for Somet, Vamatex, Panther, Dornier, Dobby, Jacquard, and Feeder machines.

- Engineered for durability and high performance.

2. Competitive Pricing & Bulk Discounts

- Cost-effective solutions for textile manufacturers.

- Special offers on large orders.

3. Fast & Secure Global Shipping

- Reliable international delivery with secure packaging.

- Ensures parts reach your facility on time without damage.

4. Expert Customer Support

- Professional assistance in choosing the right spare parts.

- Dedicated team available for inquiries and technical support.

Conclusion

Timely replacement of textile machine spare parts is crucial for maintaining productivity, reducing downtime, and ensuring high-quality fabric production. By identifying wear and tear early and sourcing reliable replacement parts from Shaoxing Jainatex Trading Company Limited, you can keep your textile machines running smoothly and efficiently.

Avoid unexpected breakdowns and costly repairs—invest in high-quality spare parts today!